Home ›Products › Foam Recycling Machine

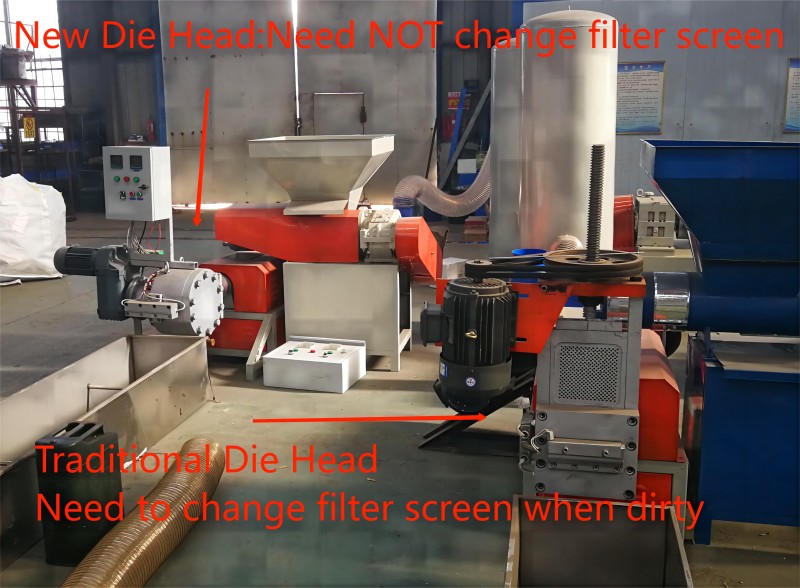

Our EPS pellets machine is optional with newly designed strand die head which is meshless (without filtering screen mesh) and it automatically removes impurity.It is diffirent with normal machines in the market.

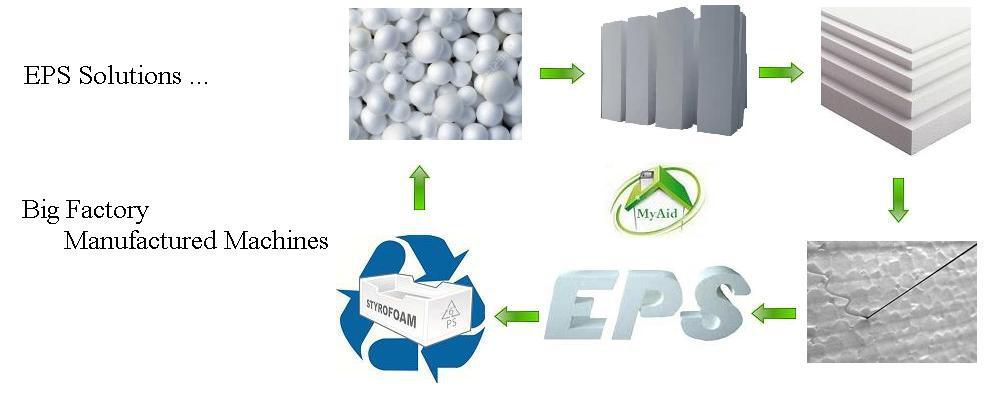

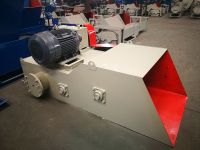

EPS pelletizing machine is also called as eps granulator recycling machine, it includes eps shredder for eps foam waste, pipe, silo, strand die granulator main machine, water channel, cutter etc and also the eps shredder for hot melting ingot and eps shredder for cold compacted bricks based on your different feedings. The line is used for making recycled eps waste into particles which can be used as raw materials for making extruded polystyrene,picture frame,insulation materials,bill board,auxiliary materials etc products.

|

Machine Model |

Mother + baby machine |

Mother Motor Power kw |

Baby Motor Power kw |

Capacity kg/h |

|

220 |

220 + 105 |

15 |

5.5 |

150 |

|

245 |

245 + 105 |

18.5 |

5.5 |

200 |

|

300 |

300 + 135 |

22 |

11 |

300 |

|

325 |

325 + 135 |

30 |

11 |

400 |

|

350 |

350 + 150 |

37 |

15 |

500 |

|

400 |

400 + 160 |

45 |

185 |

700 |

|

There are different filter die options with electric motor type,hydraulic type and die no need to replace screen. |

||||

It is automatic,dual screw type which is operated with temperature control function. The EPS pelletizing machine has the layout of upper and down melting screw.The strand die head on the machine is for making spaghetti which will be cooled in the water and then cut.

1) Screw materials are made by high carbon chromium bearing steel. Its anti-friction and anti-rust are good performance. The actual capacity is by the conditions of the feeding on the screw and the output of mold head,our machine is designed with good screw type which is by our years of experience.

2) Feeding inlet is designed considering of the different density of the materials. Customer can control the feeding speed.

3) Temprature control box enable customers know the work conditions such as the temperature of the screw,customers can adjust it depending on the noodles color. it avoid the cases of overheat or melting failure.It is also good for make more transparent particles.

4) Wire mesh auto exchange device. The device on the mold head make the machine work without stop.

5) Protection on shelter makes workers safe during work.Eps the shelter on motor and the heater. Also,it makes the machine good looking.

Application materials:

used eps foam blocks, expandable polyethylene ,such as various package foam,lunch box, foam scraps,hot meltings and cold compacted ingots or bricks etc.

Procedure: crushing ---> plastify --->spaghetti ---> cooling ---> cutting

Advice for choosing your capacity

1) Economical machine is suitable for beginners or small capacity users.

2) Model 220 with single/double reducers is suitable for 10 ton/monthly capacity.It is with temperature control box and wire mesh auto exchange device, the output particles are with good quality.

3) Model 320,350 are suitable for big capacity user who knows the filed, it is with small power and big capacity.

Application on EPS waste option

Related Items

Product Category

Hot Items

Foam Dedusting Crusher - EPS De dust machine

Foam Dedusting Crusher - EPS De dust machine New EPS Styrofoam Densifier Melts without Pre-heating Time

New EPS Styrofoam Densifier Melts without Pre-heating Time EPS pelletizing machine - strand die works without filtering screen

EPS pelletizing machine - strand die works without filtering screen CNC hot wire 2D cutting machine with wire oscillation

CNC hot wire 2D cutting machine with wire oscillation hot wire CNC foam cutting machine with turntable for 2D/3D/4D models

hot wire CNC foam cutting machine with turntable for 2D/3D/4D models full automatic and continuous eps cutting line

full automatic and continuous eps cutting line

Live Help

0086 13833131292

0086 13833131292 0086 311 86558425

0086 311 86558425

English

English Espanol

Espanol Arabic

Arabic